The Role of Packaging in Supply Chain Management

Date: November, 2017 | Category: Proofreading | Author: Marvin Magasura

The packaging industry is evolving.

We now know that packaging no longer refers to a box or a carton, but rather to a coordinated system of preparing goods for safe, cost-effective, and efficient movement throughout the whole supply chain that eventually leads to maximizing consumer value, sales, and hence profits.

This means packaging also plays an integral role in supply chain management. It protects products from damage, allows for their efficient distribution, communicates to the consumers, and is one of the major product promoters in a competitive marketplace.

In fact, packaging design has recently developed into a mature communication discipline on its own – and clients now realize that packaging is a critical and central element in the creation of an effective brand identity.

In order to achieve successful supply chain management, packaging systems have to be connected with aspects of marketing, logistics, production, and the environment.

Packaging logistics demands can be easily handled throughout all processes and for the consumers. Marketing, on the other hand, requires appealing packages that can engage customers. Production usually requires one size of packaging for all types of products to minimize time and labor costs.

Good packages satisfy all of these aspects while also fulfilling consumers’ expectations to create the desire to try the product.

Market, Flow, and Environment

The aspects mentioned before – and a few others – can summarize the packaging system into three primary functions that interact with each other in supply chain management: market, flow, and environment.

Market

The market function is fundamental to the packaging system and takes into account things like layout, design, communication, and ergonomic aspects that add to the product and brand’s value. Its whole purpose is to satisfy consumers and increase sales.

In recent decades, the connection between marketing and packaging has been deeply analyzed by several studies, most of them finding that packaging to be an instrumental part of marketing campaigns that can influence aspects like consumer attention, product positioning, evaluation and categorization, usage behavior, brand communication, and intent to purchase.

In other words, packaging plays the role of an interface between consumers and brand owners and can genuinely alter the impression of the product’s quality.

Flow

The flow function takes into account all the packaging features that contribute to easy handling in distribution. This function includes internal material flows, packaging logistics, distributions, disposal, unpacking, and return handling.

In recent years, packaging logistics has become a new discipline that has gained traction with the scientific and industrial community over the strategic role of logistics in boosting a company’s competitive advantage. Of course, both science and industry attribute different degrees of maturity to the subject depending on culture and region.

The concept of packaging logistics is now focusing on the synergy achieved by mixing the efficiency and effectiveness of supply chain management with packaging and logistics systems through the improvement of both types of activities. In other words, it is the relationship between packaging and logistic systems that increases the add-on value to the complete supply chain, from raw material producers to the disposal of empty packages via recycling, landfill, or incineration.

Environment

Yet in current operational environments, these innovations must also take into consideration not only the market and flow functions but also an equally important and increasingly emerging factor: the environmental function. It aims to lower the negative impact of the packaging process on the environment, focusing on issues like using fewer inputs while achieving the same outputs, reusing materials, and facilitating the recycling of said packaging.

In fact, an increasing number of businesses are now choosing environmentally friendly approaches and techniques since it became clear that packaging has a substantial influence over the environmental aspect of the supply chain.

Enhanced Labeling and Traceability

The primary goal of supply chain management has always been achieving customer satisfaction. However, we have to keep in mind multiple variables can obstruct this process. Packaging, in particular, can affect a product’s dependability, quality, speed, costs, and flexibility, while also having an impact on its life cycle. For companies trying to optimize all the factors that play a prominent role in their supply chain, barcode label software might be the answer.

Enhancing product traceability is one of the critical improvements any company can make to enhance its supply chain management. Traceability integrates inventory, transportation, and manufacturing while affecting the overall cost. For a long-term customer satisfaction strategy focused on product packaging, companies need to enhance their traceability and deliver such improvements to customers through supply chain labeling and packaging.

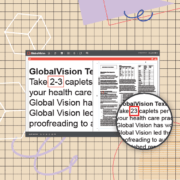

GlobalVision’s barcode inspection software becomes an ally to companies with barcode traceability systems already in place. It allows for the automatic inspection and grading of both digital artwork and print. The software uses a state-of-the-art recognition system that also ensures all barcodes are compliant with ISO 15415/15416 and ANSI standards and delivers barcode inspection reports that let you know about possible adjustments.

As we tear down the layers between the creation of a product and its ultimate sale, the importance of traceability and labeling in the supply chain becomes readily apparent. Increased supply chain management costs end up being paid by the consumer, while traceability and labeling improvements, on the other hand, might even enhance sales through packaging enhancement.

Furthermore, packaging options are continually evolving, with new labeling and material options specifically developed to boost customer engagement and increase the overall packaging quality.

These too have an impact on the user experience and ultimately the sale of a product. So, to maintain business growth, companies should focus on aligning their supply chain management, labeling, and traceability needs.

Conclusion

Packaging today involves far more than boxes and bags, but even though there has been an incredible revolution in the industry, the optimization of packaging still needs to be at the center of any efforts to enhance one’s supply chain management.

Countless marketing studies have concluded that optimized packaging actually delivers results, with regard to many aspects of the supply chain. It can increase product efficiency, smooth the handling of materials on the production floor, ensure the efficient use of modern supply chain technologies like stackers and pallets, and make for easier damage control, inventory management, cycle counts, and space usage.

Simply put, packaging optimization also optimizes overall supply chain costs, leading to a maximized return on investment.

If you want to optimize your supply chain management through the addition of traceability and barcode label software, request a demo of GlobalVision to see how automation can improve your workflow processes.

SECURING THE BRAND PACKAGING WORKFLOW

Read our white paper on how to automate printed packaging quality control

and the different techniques and systems that can be used in the packaging workflow.

Download the Whitepaper