Why Error-Free Packaging and Labeling Is a Must

Date: November, 2018 | Category: Proofreading | Author: Ryan Szporer

Pristine, error-free packaging, and labeling undeniably look good, but it’s more than that. It’s a necessity, regardless of the industry in question. Of course, it conveys brand strength, but, more importantly, it’s about respecting regulations that were put in place for a reason.

Mislabeling Misadventures

The strength of those regulations (and the severity of the penalties for breaking them) depends on the country. For example, in the United States, the Fair Packaging and Labeling Act with the Uniform Packaging and Labeling Regulation (UPLR; and National Institute of Standards and Technology Handbook 130) require consumer commodities to clearly disclose packaging’s contents and manufacturer info. The goal is for customers to be able to make informed purchasing decisions through the comparison of accurate price and quantity information on packaging.

Additional regulations meanwhile outlaw deceptive packaging and labeling. At both the federal and state levels, false advertising and labeling laws exist, with offenders risking additional liability to any victims. Victims can include consumers who are harmed by the product or businesses further down the supply chain who unwittingly purchased the product. If, on the other hand, a party down the supply chain discovers the fraud but fails to take action, they could be responsible too.

The aforementioned laws are admittedly not all-encompassing. State laws can differ and the FPLA sometimes delegates regulatory and enforcement responsibilities to the agencies who oversee individual industries instead. For example, the Food and Drug Administration regulates packaging and labeling in the food & beverage, cosmetics, medical devices, and pharmaceuticals sectors.

Food and Drug Labeling as a Case Study

Taking the food & beverage sector as an example, put simply, the packaging must contain what the label says it does. If the FDA has reason to believe packaging is inaccurate, that it falsely claims the product inside is 100% fruit juice, for example, imports can be detained without physical examination. The product effectively gets prevented from being distributed (and sold).

When a manufacturer is a guilty party, the FDA may issue a warning. In the event the manufacturer does not comply and correct the issue, the FDA takes additional legal action to ensure the product gets removed from the market, without it being permitted to return until the issue has been corrected. Criminal fines and even prosecution may result depending on the infraction.

Fines up to $500,000 for misdemeanors that result in death can be doled out. A misdemeanor, which would not require proven intent, can also result in up to one year in prison. A felony, which implies intent or a subsequent violation after the first, can lead to a maximum of three years instead.

In the case of the pharmaceutical industry, which is also under the purview of the FDA and whose customers depend on packaging for accurate dosage information, it’s easy to see why penalties need to be especially severe. A single misplaced period can have huge negative ramifications.

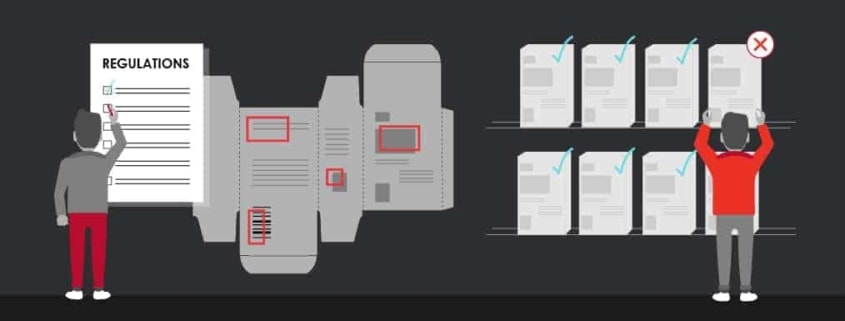

Performing Labeling and Packaging Inspections

A packaging or label error doesn’t have to be fraudulent to be costly. In fact, a great deal of mistakes are simply caused by human error. Market research indicates that 60% of product recalls are caused by workers. And it’s easy to see why. Typos can easily be created and then missed due to proofing fatigue during the artwork-creation and printing processes.

It only reinforces the need for failsafes, like a digital inspection platform, to improve upon the efficiency of a company’s quality control. Performing labeling and packaging inspections at each stage of the workflow reduces the risk of a recall and the number of required revision cycles, so products get to market faster, without any errors.

Inspections are going to be performed anyway, including potentially by the governing body in the question itself. It only makes sense that a company would want to put its best foot forward in preparation. Having previously integrated robust quality systems is one key to success in such an instance. Not having to correct an error after the fact is another key to success in general.

There is obviously a difference between fraudulent practices and innocent errors that simply do not get caught in time. Unfortunately, they can each have severe consequences. What separates them from one another is how, instead of actively trying to skirt regulations, companies can actively try to prevent mistakes. It just takes a conscious effort to improve upon internal processes.

_________________________________________________________________________________________

Get your complete guide to meeting FDA labeling requirements here

Learn how some of the world’s top pharma companies have cracked the efficiency code with automation